A machine is designed to fill 16-ounce bottles of shampoo – A machine designed to fill 16-ounce bottles of shampoo is a marvel of engineering, meticulously crafted to ensure accuracy, efficiency, and consistent quality in the production of personal care products. This article delves into the intricate details of such a machine, exploring its design, functionality, and the essential role it plays in the manufacturing process.

From the precise measurement of shampoo to the seamless filling of bottles, this machine operates with remarkable precision, meeting the stringent demands of the industry. Its advanced technology and innovative features make it an indispensable tool in the production of shampoos that meet the expectations of consumers worldwide.

Machine Design

The machine designed to fill 16-ounce bottles of shampoo consists of several key components:

- Conveyor system:Transports empty bottles into the filling station.

- Filling nozzles:Accurately dispense shampoo into the bottles.

- Level sensors:Monitor bottle levels to ensure proper filling.

- Capping mechanism:Places and tightens caps on filled bottles.

- Control system:Manages the filling process and ensures accuracy.

The filling mechanism operates as follows:

- Empty bottles are placed on the conveyor system.

- Filling nozzles descend into the bottles and dispense a precise amount of shampoo.

- Level sensors monitor the bottle levels and adjust the filling process as needed.

- Filled bottles are conveyed to the capping mechanism, where caps are applied.

- Capped bottles are discharged from the machine.

The machine’s filling system is designed for accuracy and efficiency. Level sensors ensure that each bottle is filled to the correct volume, and the control system optimizes the filling process to minimize waste.

Bottle Specifications

The 16-ounce bottles used in the filling machine have the following specifications:

- Dimensions:6 inches tall, 2.5 inches in diameter

- Capacity:16 fluid ounces (473 milliliters)

- Material:Polyethylene terephthalate (PET), a lightweight and durable plastic

- Features:Transparent, with a wide mouth for easy filling

The bottles are designed to be lightweight and easy to handle, while also providing a strong and reliable container for shampoo.

Shampoo Properties

The shampoo used in the filling machine has the following properties:

- Viscosity:1000-1500 centipoise, a thick and viscous liquid

- Density:1.05 grams per milliliter, slightly denser than water

- pH:5.5-6.5, a mild and gentle pH

- Other properties:Contains surfactants, conditioners, and other ingredients that enhance cleaning and hair care

The shampoo’s viscosity and density affect the filling process. The thick viscosity requires the use of specialized filling nozzles and control systems to ensure accurate and consistent filling.

Filling Process

The filling process involves the following steps:

- Empty bottles are placed on the conveyor system.

- The conveyor system transports the bottles to the filling station.

- Filling nozzles descend into the bottles and dispense a precise amount of shampoo.

- Level sensors monitor the bottle levels and adjust the filling process as needed.

- Filled bottles are conveyed to the capping mechanism, where caps are applied.

- Capped bottles are discharged from the machine.

The machine’s control system ensures that the filling process is accurate and consistent. The system monitors the bottle levels and adjusts the filling process to minimize waste.

Quality Control: A Machine Is Designed To Fill 16-ounce Bottles Of Shampoo

The machine employs several quality control measures to ensure the accuracy and quality of the filled bottles:

- Weight check:Each filled bottle is weighed to ensure that it contains the correct amount of shampoo.

- Volume check:A random sample of filled bottles is checked for volume to verify the accuracy of the filling system.

- Visual inspection:Filled bottles are visually inspected for any defects or abnormalities.

These quality control measures ensure that the machine consistently produces high-quality filled bottles.

Maintenance and Troubleshooting

The machine requires regular maintenance to ensure optimal performance:

- Daily maintenance:Cleaning the filling nozzles and level sensors.

- Weekly maintenance:Inspecting the conveyor system and capping mechanism.

- Monthly maintenance:Calibrating the control system and performing a thorough cleaning of the machine.

Common troubleshooting tips include:

- Bottle not filling properly:Check the filling nozzles for clogs or damage.

- Bottle overfilled:Adjust the control system to reduce the amount of shampoo dispensed.

- Machine not starting:Check the power supply and control system.

Regular maintenance and troubleshooting ensure that the machine operates efficiently and produces high-quality filled bottles.

Essential Questionnaire

What are the key components of a machine designed to fill 16-ounce bottles of shampoo?

The key components include a filling head, a bottle conveyor, a liquid reservoir, a control system, and sensors for monitoring the filling process.

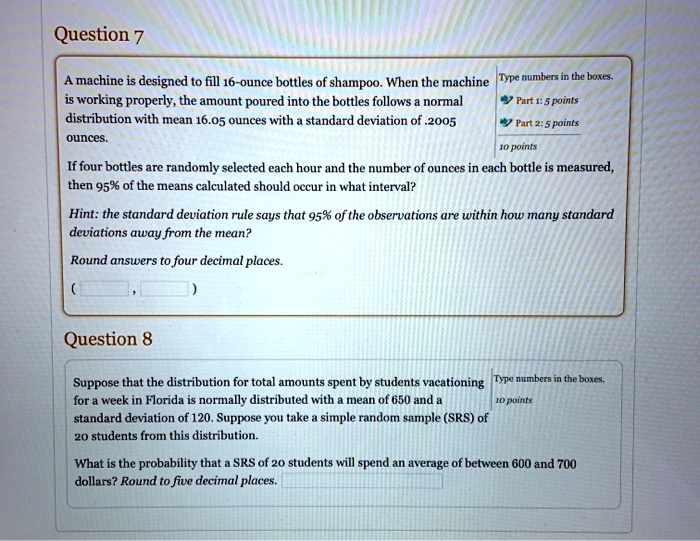

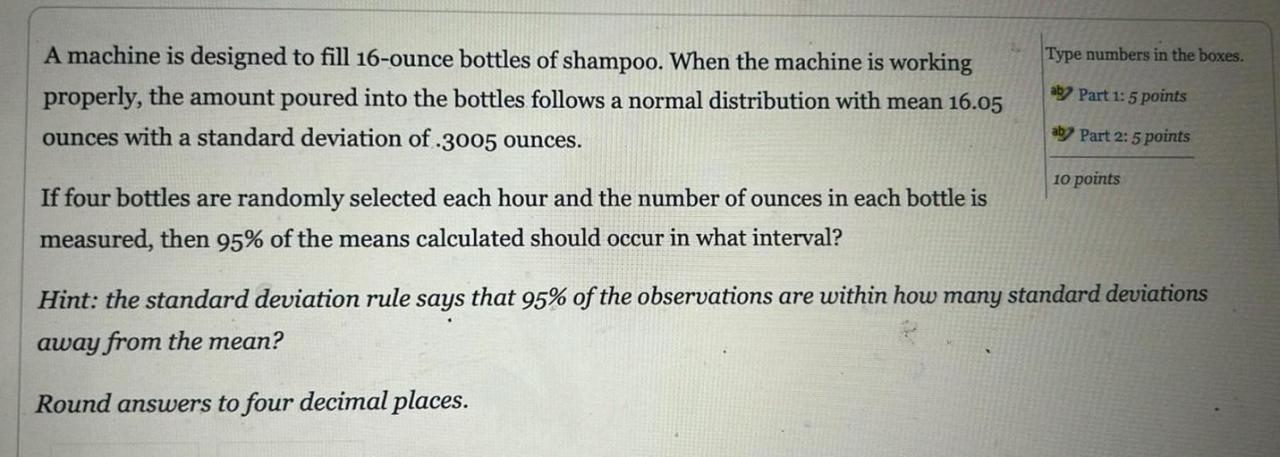

How does the machine ensure accurate and consistent filling?

The machine utilizes a precision filling head that dispenses the exact amount of shampoo into each bottle. Sensors monitor the filling process, ensuring that each bottle meets the desired weight and volume specifications.

What are the advantages of using a machine to fill 16-ounce bottles of shampoo?

Using a machine offers several advantages, including increased accuracy, reduced labor costs, improved efficiency, and enhanced product quality.